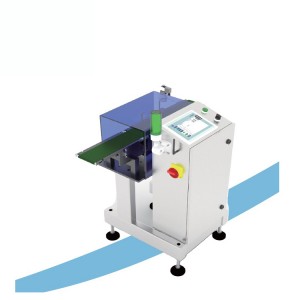

IoT Optimization Preferred Medium & High Speed Dynamic Checkweigher MCS-H

Short Description:

IoT Optimization Preferred Medium & High Speed Dynamic Checkweigher MCS-H

Full Range of Checkweighers

Dynamic checkweigher series products include medium and low-speed checkweighers suitable

for vertical packaging machines, high-speed checkweighers suitable for pharmaceutical and food quality inspection, and large-scale checkweighers suitable for packaging and logistics industries. Heavy technical performance is very good. global series of products are committed to assisting the needs of online production weighing, quality inspection, etc. in hardware, food, pharmaceutical, daily necessities, logistics and other industries, and provide one or more solutions. In addition, also provides integrated solutions, through the combination of dynamic checkweighers and other product inspection technologies (such as: metal detection, X-ray inspection and visual inspection), so as to meet the more comprehensive needs of customers and provide more complete solutions .

Total solution

Comprehensive solution of dynamic checkweigher and metal detector system

Comprehensive solutions for dynamic checkweighers and packaging machines

Comprehensive solutions for dynamic checkweighers and labelling machines (jet printers)

Supported by distributors and ancillary suppliers around the world

Diverse product options

Up to 20 standard dynamic checkweighers and additional optional devices

Provide a variety of ranges and materials (eg: carbon steel spray, aluminum alloy,

stainless steel) to meet different needs and environments

Provides a variety of data communication standards

(Example: Ethernet, RS485 and RS232 technology), which can realize seamless connection with data network suppliers around the world

Remote maintenance technology, support remote maintenance and remote upgrade

Support Industrial cloud and IOT integration mechanism

Feature:

Applicable to the back-end re-inspection of the packaging line

Customized for complex and precise applications

Support Industrial cloud

Maintain high performance in harsh environments

Support compliance with data collection

Weighing range: 10 g - 500 g

Accuracy: ± 0.2 g ~ 1 g

Working efficiency: ≤120 pieces/min

Touch screen size: 7 inches

Production Size: